|

||||||||

|

|

|

|

|

|

| New Equipment - Burn Off Ovens | |||||

ECO Burn-Off Ovens has over two hundred years of combined experience in the industry. Together our company is committed to providing innovative, highly engineered, quality, and cost effective burn-off ovens to meet customer’s individual needs. ECO Burn-Off Ovens mission is to always surpass customer’s expectations. ECO Burn-Off Ovens are designed with automated controls to minimize cycle time, allowing the oven to reach highest efficiency and not emit any harmful toxins into the environment. Organic coatings such as paint, varnish and related products are placed in a load. The chemically decomposing organic material (grease, oil, paint, etc.) begins to burn-off at elevated temperatures in the absence of oxygen. Heat is released into the burn-off oven; no flame physically contacts any items put in the load. Once the cycle is complete organic material is turned into ash that may be rinsed or shot-blasted and the items are now ready to be put back in production. ECO Burn-Off Ovens are secure, trusted, easily operated, ecologically sound and save customers money. |

|

||||

| ECO Burn-Off Ovens - Industries | |||||

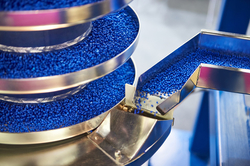

| Powder Coating Providers Using heat cleaning technology, ECO Burn-off Ovens remove paint from racks, hooks, and other organic material that must be cleaned systematically to simplify the coating process. Once the cycle is complete the organic material is turned into ash. The product can be rinsed or shot blasted and placed back into production. |

|

||||

|

|||||

| Automotive and Engine Rebuild ECO Burn-Off Ovens allow automotive re-builders the capability to safely eliminate any oil, grease, varnish and other organic material from bearings, engine blocks and other metal parts. Automotive re-builders are able to maximize their production capability. |

|

||||

|

|||||

| Electric Motor Rewind ECO Burn-Off Ovens allow motor re-builders the capability to safely eliminate any adhesives and varnish from stators or other metal parts. No harm is done to the product and once the load is through processing stators are ready for winding. Motor re-builders are able to improve motor reliability and will see a drop in their operating cost. |

|

||||

|

|

|

|

|

|

| Slocum Equipment, Inc. 3528 Quaker Lane · North Kingstown, RI 02852 Toll Free: 888.310.2680 · Local: 401.294.0001 |

|

|