| |

| New Equipment - Batch Powder Coating Systems |

|

Slocum Equipment offers innovative, state of the art, energy efficient powder coating systems. From the smallest job shop to the largest manufacturer, Slocum has you covered with over 20 years of first hand design-build experience.

We offer true turnkey service overseeing the fabrication, installation and commissioning of every system we sell. Call us today for a free consultation and let us show you what the meaning of the word service is.

|

|

|

| |

| Powder Coating Booths |

|

|

|

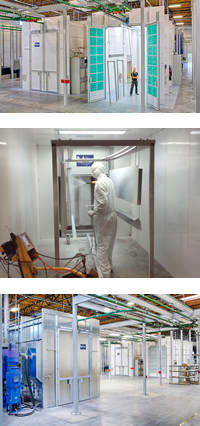

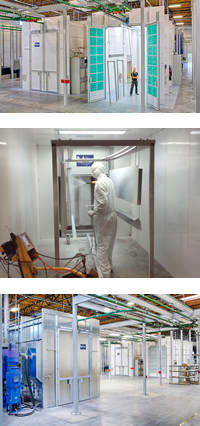

Batch Powder Booths

Our Cartridge Batch Powder Booths feature an open front (also know as open face) design and are ideal for small to mid-size powder applications. To ensure cartridge filters remain clean, this booth is built with a purge control feature, which assures the safe operation of the coatings enclosure by maintaining the airflow at design levels. During operation, powder accumulates on the cartridge filters, and as the cartridge filters load, airflow decreases and negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of accumulated powder to ensure maximum filter life.

Booth Features

RTT booths are constructed from heavy duty 18-gauge, prime quality galvanized steel and engineered with corresponding support structure.

All panels and support members are laser cut and precision formed for consistent fit allowing for easy nut and bolt assembly.

Collector Module recirculates clean, filtered air into the booth and includes high quality primary filter and final filter modules. Factory-assembled, powder coated white mild steel construction with removable powder drawer.

LED lighting is constructed of 22-gauge steel which is powder coated white, and available in 4000 and 8000 lumen models. E-Lights are ETL listed for US and Canada with Class 1 Division 2, Group A, B, C, D and Class 2 division 2, Group F and G ratings.

Control Equipment Includes NEMA 12 UL and ETL listed control panel mounted to the side of the collector module, factory wired and tested. Automatic or manual cartridge filter pulse down mode; Door mounted magnehelic gauge for cartridge filter monitoring; VFD to control fan speed; Pressure switches to monitor final filter pressure and warn/ shutdown if pressure exceeds set point.

Air solenoid valve interlocked to the exhaust fan and air supply for the spray application equipment.

RTT booths meet and/or exceed quality performance standards and all applicable OSHA and NFPA regulations.

|

|

|

|

|

|

| |

|

Batch Powder Booths

Rohner Batch Cartridge Recovery Booths are designed with optimal airflow for powder containment and application efficiency, and are the perfect solution for bringing the advantages of Batch Non-Reclaim Powder Booth to your powder coating process. Our standard powder coating booths control air uniformly through all the booth openings, recirculating the air back into the facility so no makeup air is required, and collecting excess powder through the two-stage filters of the collector modules. Rohner Batch Cartridge Recovery Booths provide a superior application environment for small job shop runs or large production runs, and are designed for manual gun usage.

STANDARD FEATURES PROVIDED IN ROHNER BATCH CARTRIDGE RECOVERY BOOTHS INCLUDE:

• Premium 18 gauge G90 Galvanized steel construction

• AMCA certified aluminum blade fans with TEFC motor standard

• UL listed color correct fluorescent light fixtures

• 20 x 20 industry standard filters

• 100 F.P.M. standard booth velocity

• Welded tube steel product doors

• Easy nut & bolt assembly with 3D exploded view drawings |

|

|

|

|

|

| |

| TOP |

| Powder Coating Ovens |

|

|

Batch Ovens

If flexibility, reliability, and efficiency are what you are looking for, then a GAT Batch Oven is the perfect fit for you. GAT batch ovens feature 4” thick, 4# mineral wool batt insulated 18 gauge oven panels, utilizing their own tongue and groove design along with their patented isolator spreader clip and stiffener channel construction, GAT batch oven panels have 40% fewer seams and no hot spots.

GAT Batch ovens are suitable for wet paint or powder coat paint applications and have a maximum operating temperature of 500 deg. F

All GAT Batch Ovens are are pre-fired and tested at the factory prior to shipment and come with insulated stack packages up to 20 feet long. Standard delivery is 6-8 weeks but expedited builds are available for those on tight schedules. GAT batch ovens come in eighteen standard sizes and you can order your oven in many different configurations. Standard batch ovens options include;

6’x6’, 8’x8’, 10’x10’ by 10’ deep up to 30’ deep configurations standard

Single Set of Doors or Doors on Both Ends

Conveyor Slots Floor Options -Insulated Floor-12 Ga. Steel floor-No Floor- Insulated Floor with Cart Slots

208v 75 amps- 208v-480v 60 amps-460-480v- 30 amps 3phase. Propane or Natural Gas fired |

|

|

|

| |

ECO Burn-Off Ovens has over two hundred years of combined experience in the industry. Together our company is committed to providing innovative, highly engineered, quality, and cost effective burn-off ovens to meet customer’s individual needs. ECO Burn-Off Ovens mission is to always surpass customer’s expectations.

ECO Burn-Off Ovens are designed with automated controls to minimize cycle time, allowing the oven to reach highest efficiency and not emit any harmful toxins into the environment. Organic coatings such as paint, varnish and related products are placed in a load. The chemically decomposing organic material (grease, oil, paint, etc.) begins to burn-off at elevated temperatures in the absence of oxygen.

Heat is released into the burn-off oven; no flame physically contacts any items put in the load. Once the cycle is complete organic material is turned into ash that may be rinsed or shot-blasted and the items are now ready to be put back in production. ECO Burn-Off Ovens are secure, trusted, easily operated, ecologically sound and save customers money. |

|

|

|

|

| TOP |

| Pretreatment |

|

Electro-Steam Generators

These steam units specifically designed for pre-cleaning and iron-phosphating metal surfaces prior to powder coating.

Benefits of pre-cleaning and iron-phosphating systems vs. other systems:

Clean, smooth, and receptive surface recommended for paint and powder coating processes. Prevents the spread of undercoat corrosion for surfaces that have been nicked or scratched.

Large spray booths are not required since there is very minimal overspray. Uses approximately 50% less chemical than a pressure washer system. Produces much less waste water than other systems. Savings generated as a result of fewer chemicals, less water, and less effluent.

Additional benefits include the following:

Standard Stainless Steel Cabinets

Built in accordance with ASME, UL, and CSA requirements

National Board of PVI Shop Inspected

98% efficient resulting in energy and water conservation

Low or high pressure dry steam in less than 15 minutes (or on demand)

A one year warranty on all parts and a five year warranty on the chamber. |

|

|

|

| |

Re-defining ‘clean’ for any industry

DINAMEC and SCHWING offers the solution for all your metal stripping needs. Our solutions safely remove all organic substances from all kinds of metal parts no matter the industry. From paint, powder coating, plastic, polyesters, and rubber, we can remove it. Our machines can be found in a wide variety of industries with over 2,000 installations worldwide. We ensure a clean and healthy stripping alternative to more traditional methods. Our technology offers many benefits from optimal results, no abrasive damage to tools or parts and a high operating capacity with low operating cost.

Decoring and Sand Reclamation, and Heat Treatment

Looking to remove the sand cores from your aluminum castings? This is often a tedious job due to the integrated design and hard organic binders. The Dinamec Systems’ Deco Fluid Bed Installation is the perfect solution for the gentle and smooth decoring of aluminum parts. Traditional methods take long periods of time, cause deformation or damage and have a high operating cost. Our systems offer quick cleaning time, no damage of parts and all at a lower operating cost. We are your decoring solution.

|

|

| TOP |

| Powder Application |

|

Gema Manual Powder Coating Guns

Power - Quality - Control

The new generation of OptiFlex Pro manual units impresses with additional application performance due to the outstanding PowerBoost technology. With OptiFlex Pro, you easily process all powder types and coat complex parts in superior quality - all this worldwide and in the most difficult industrial environments.

The First Choice in Manual Powder Coating

The OptiFlex Pro manual units are uncompromisingly and agilely designed for maximum industrial suitability and worldwide use. The intelligent and durable components fit perfectly together and form the powerful package for superior manual powder coating. The ergonomic and intuitive operation enables every user to achieve the best coating results at any time. |

|

|

|

Hertz Compressors / Air Dryers

HVD Series

HERTZ HVD series variable-speed compressors drive the motor with the frequency converter to adjust the compressor operation speed according to compressed air requirements and save up to 35% energy. Thanks to its high-quality equipment and excellent engineering in its design, it provides a very efficient and flexible use as per requirements.

Advantages

Up to 35 % energy saving* Operation at constant output pressure value Wide operating pressure range (100-175 psi) Soft starting Protection against the adverse effects of peak currents *When compared with compressors without an inverter for business with variable requirements

Main Motor and Drive System

Directly coupled one on one (1:1) with the elastic coupling Variable-speed starting with frequency converter High temperature protection with motor bearings (HVD 5-300)

Cooling System

Temperature controlled on-off type fan (HVD 5-22) Cooling fans controlled with secondary fan inverter (HVD SERIES 30-300) Independent radiator segments Silent and slow speed Radial fan (HVD 18-300) Quiet and efficient axial fan (HVD 5-15)

Other Features

High temperature sensor for motor bearings (HVD 55-300) All air and oil tanks to comply with ASME standards

Additional Options to the General Options List

Model options with Tank, without Tank, with tank&dryer (HVD 5-15)

Electronic Control

Hertz Kompressoren rotary screw compressors are equipped with easy-to-use, robust and long-lasting microprocessor controllers with communication capabilities as per the product line to ensure smooth operation and uninterrupted production.

Screw Block

Patented and durable screw block that provides high-capacity of air, and that is specially selected for each model's capacity requirement Production of air with less loss of air, thanks to the new rotor profiles, and lower torque requirements New generation bearing design with increased load carrying capabilities

Air Oil Separator

Easy-to-detach spin-on type separator (HVD 5-15) High-efficiency immersion type separator with long service life (HVD 18-300) High performance separation with three-stage design More efficient separation at lower volume with deeply wrapped, intertwined separation layers Low amount of oil mist in outlet air ≤ 3 ppm

Main Motor and Drive System

Premium 230-460 /3 phase/60Hz, IE3 IP55 electric motors with F Class insulation, Wye-Delta motor starting system. Long-lasting and efficient transfer system thanks to use of elastic couplings on direct coupled models.

|

|

|

|

| TOP |

|

|

|